Effect of Milling Strategy on the Distribution and Retention of Bioactive Compounds in Tritordeum Flour

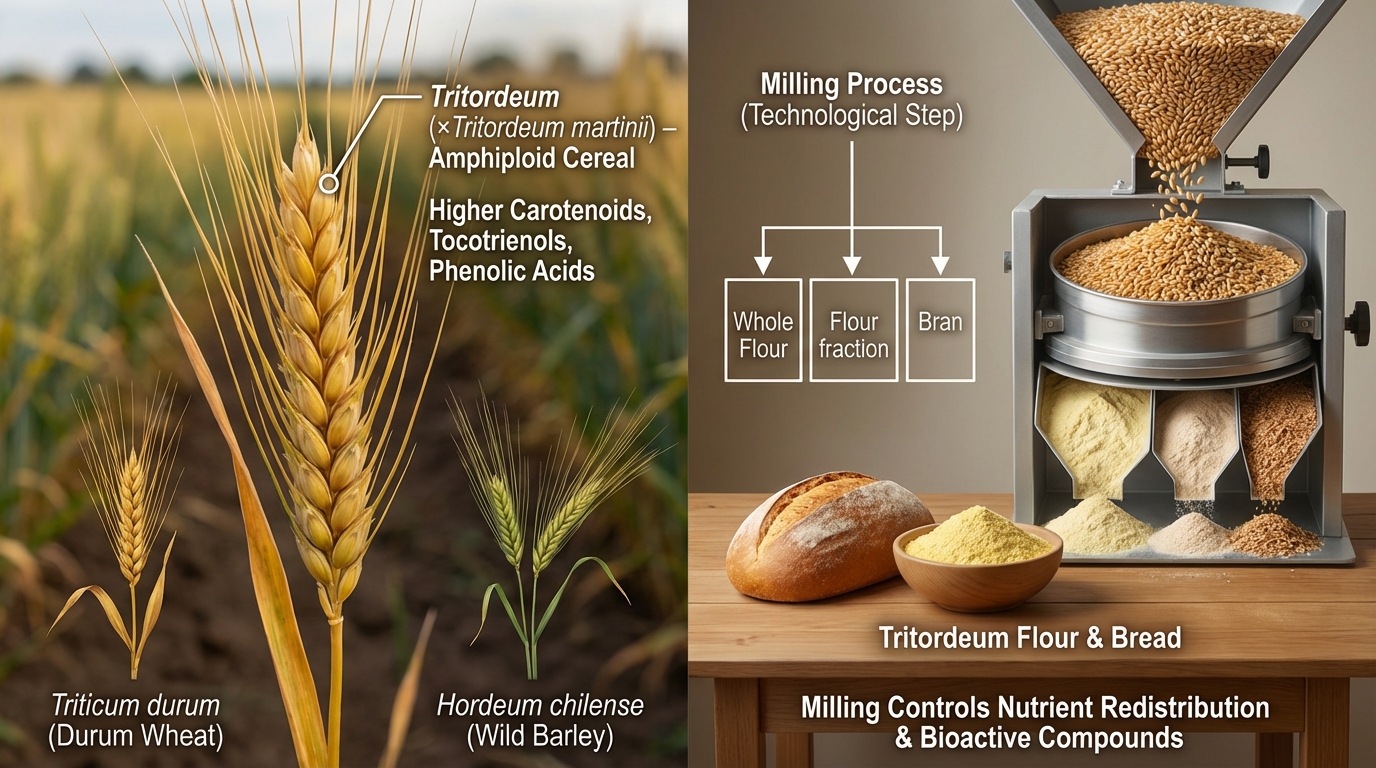

Tritordeum (×Tritordeum martinii), a cereal derived from durum wheat and wild barley, is characterised by naturally high levels of bioactive compounds, notably lutein-rich carotenoids, tocotrienols, and phenolic acids. Scientific evidence demonstrates that the nutritional expression of these compounds is strongly influenced by milling strategy, making milling a key control point in Tritordeum valorisation.

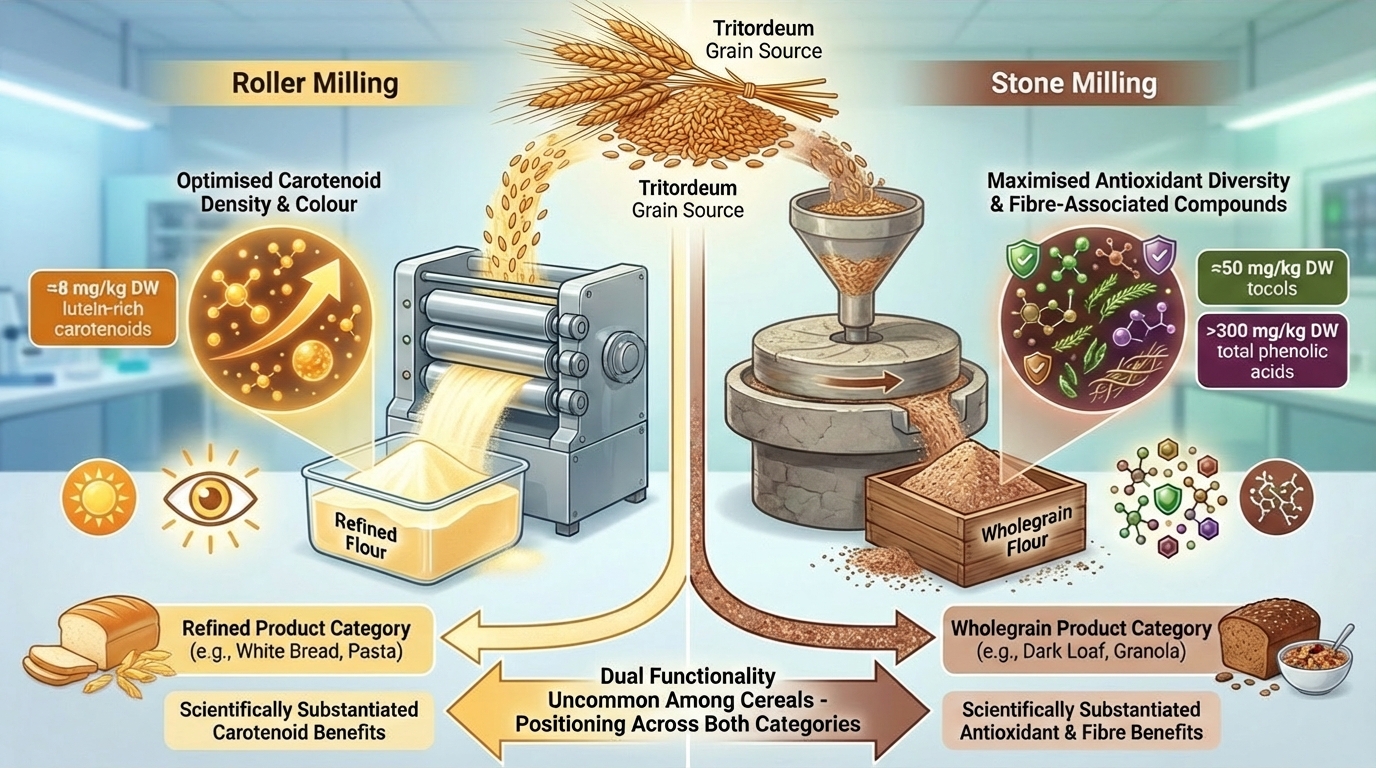

Bioactives are unevenly distributed within the kernel: carotenoids are mainly associated with the endosperm, while tocotrienols, phenolic acids and β-glucans are concentrated in the germ and outer layers. Consequently, roller milling produces refined Tritordeum flours with high carotenoid density (≈7.5–8.0 mg/kg dry weight), whereas stone milling maximises antioxidant diversity, delivering substantially higher levels of tocols and phenolic acids.

Across multiple food-processing scenarios, Tritordeum consistently retains higher levels of bioactive compounds than bread wheat, regardless of milling method. These findings confirm that milling is not a neutral operation but a strategic lever enabling targeted nutritional design, positioning Tritordeum as a flexible and evidence-based cereal platform for next-generation food products.

ARTICLE TYPE:

This article is a science-based technical review that analyses how milling strategies influence the distribution and retention of bioactive compounds in Tritordeum flour. It integrates quantitative data from peer-reviewed studies to compare roller and stone milling and their interaction with food processing. The article is intended to support evidence-based decision-making in cereal milling, product development, and nutrition-focused innovation.

- BLOG -

Check our Latest Posts

READING TIME:

10 min

CONNECT WITH US:

ARTICLE:

Read Mode Prevent your screen from going dark as you read.

1. Scientific background

Tritordeum (×Tritordeum martinii), an amphiploid cereal derived from durum wheat (Triticum durum) and wild barley (Hordeum chilense), has attracted increasing interest due to its distinctive nutritional profile. Multiple studies have shown that Tritordeum grains and flours contain higher concentrations of carotenoids (notably lutein), tocotrienols, and phenolic acids than conventional bread wheat [1–3].

However, the nutritional potential of Tritordeum is not solely determined by genotype. Milling represents a decisive technological step, as it controls the redistribution of kernel tissues and, consequently, the concentration and form of bioactive compounds in flour and final foods [1,2].

2. Kernel localisation and fractionation of bioactive compounds

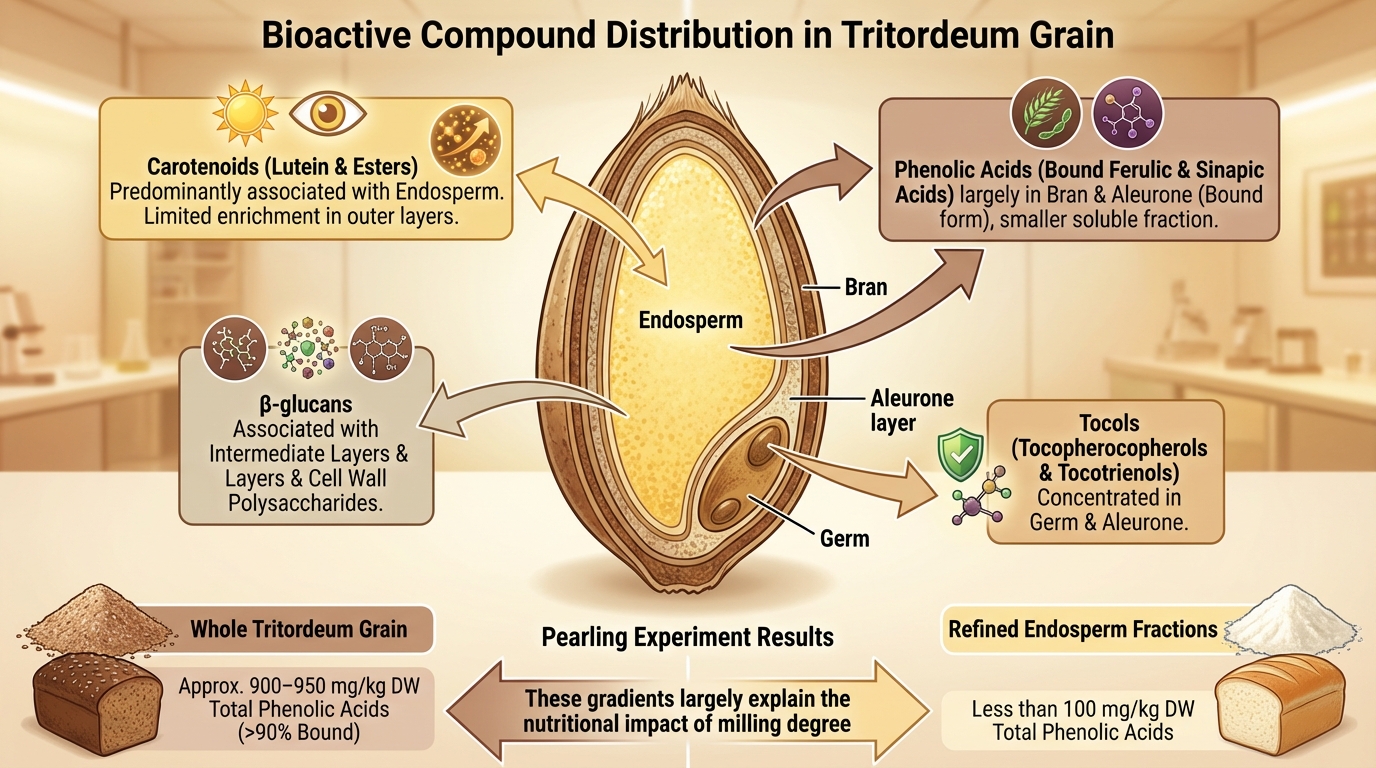

Bioactive compounds in Tritordeum are heterogeneously distributed across kernel tissues:

Carotenoids, mainly lutein and lutein esters, are predominantly associated with the endosperm, with relatively limited enrichment in the outer layers [2].

Tocols (tocopherols and especially tocotrienols) are concentrated in the germ and aleurone.

Phenolic acids are largely present in the bran and aleurone, mainly as cell wall-bound compounds (ferulic and sinapic acids), with a smaller soluble fraction [1].

β-glucans are associated with intermediate kernel layers and cell wall polysaccharides.

Pearling experiments showed that whole Tritordeum grain contains approximately 900–950 mg/kg dry weight (DW) of total phenolic acids, over 90% of which are in the bound form. In contrast, refined endosperm fractions contain less than 100 mg/kg DW [2]. These gradients largely explain the nutritional impact of milling degree.

| “The nutritional value of Tritordeum flour is shaped by where bioactive compounds are located within the grain.”

3. Quantitative impact of milling strategy on Tritordeum flour

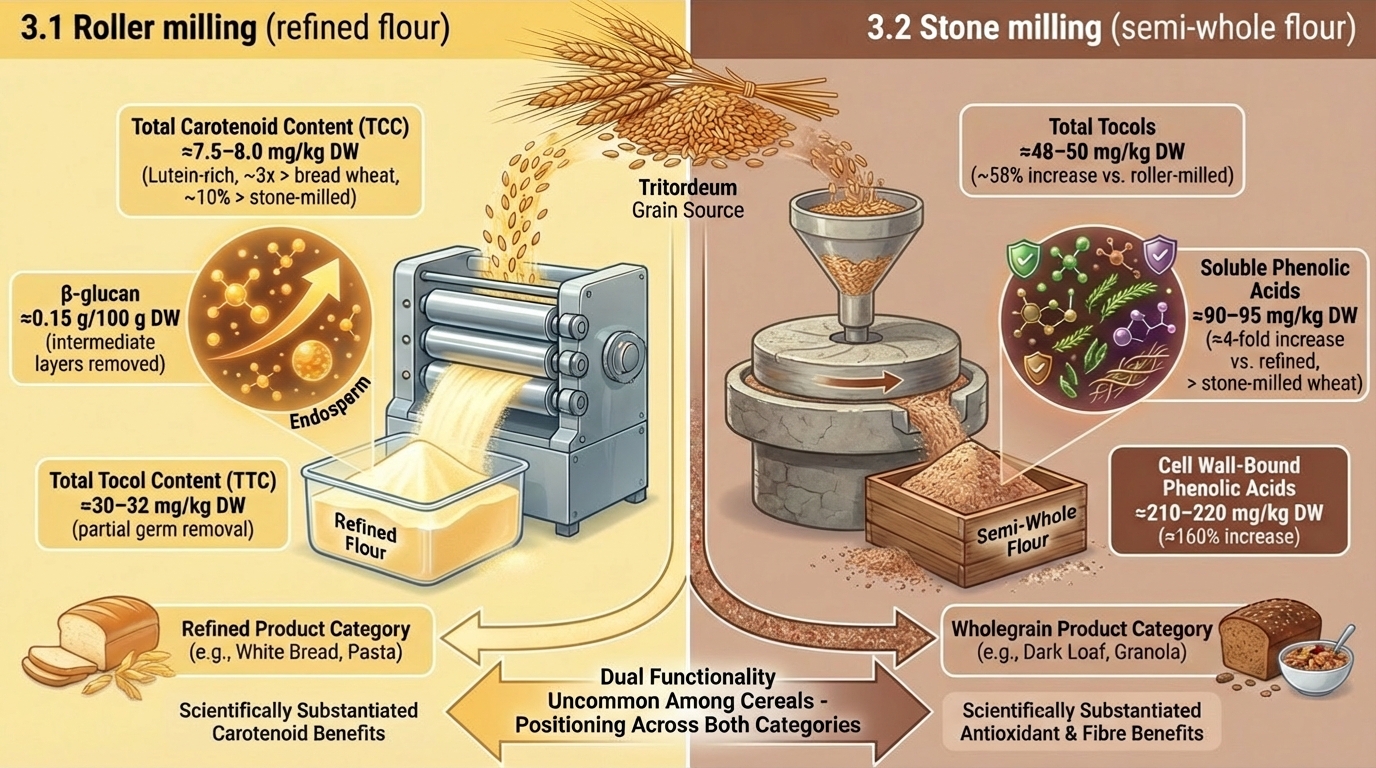

3.1 Roller milling (refined flour)

Industrial roller milling selectively retains endosperm and removes most bran and germ fractions. In Tritordeum, this results in:

Total carotenoid content (TCC) of approximately 7.5–8.0 mg/kg DW, compared with ~2.5–3.0 mg/kg DW in refined bread wheat flour [1].

Roller-milled Tritordeum flour contains about three times more carotenoids than wheat and around 10% more than stone-milled Tritordeum flour.β-glucan content of about 0.15 g/100 g DW, reflecting the removal of intermediate kernel layers [1].

Total tocol content (TTC) of approximately 30–32 mg/kg DW, due to partial germ removal [1].

Notably, unlike wheat, roller milling in Tritordeum does not reduce carotenoid concentration, as lutein is largely endosperm-associated [1,2].

3.2 Stone milling (semi-whole flour)

Stone milling retains most kernel components, leading to a markedly different nutritional profile:

Total tocols increase to approximately 48–50 mg/kg DW, representing a ~58% increase compared with roller-milled flour [1].

Soluble phenolic acids reach about 90–95 mg/kg DW, compared with ~22 mg/kg DW in refined flour (≈4-fold increase) and ~50 mg/kg DW in stone-milled wheat [1].

Cell wall-bound phenolic acids increase to approximately 210–220 mg/kg DW, compared with ~80–85 mg/kg DW in refined flour (≈160% increase) [1].

Statistical analysis indicates that milling degree alone explains up to 98% of the variance in bound phenolic acid content, highlighting milling as the dominant driver of antioxidant retention [1].

| “Unlike wheat, refined Tritordeum flour can concentrate carotenoids rather than dilute them.”

| “Stone milling unlocks the antioxidant and fibre potential stored in Tritordeum’s outer kernel layers.”

4. Interaction between milling and food processing

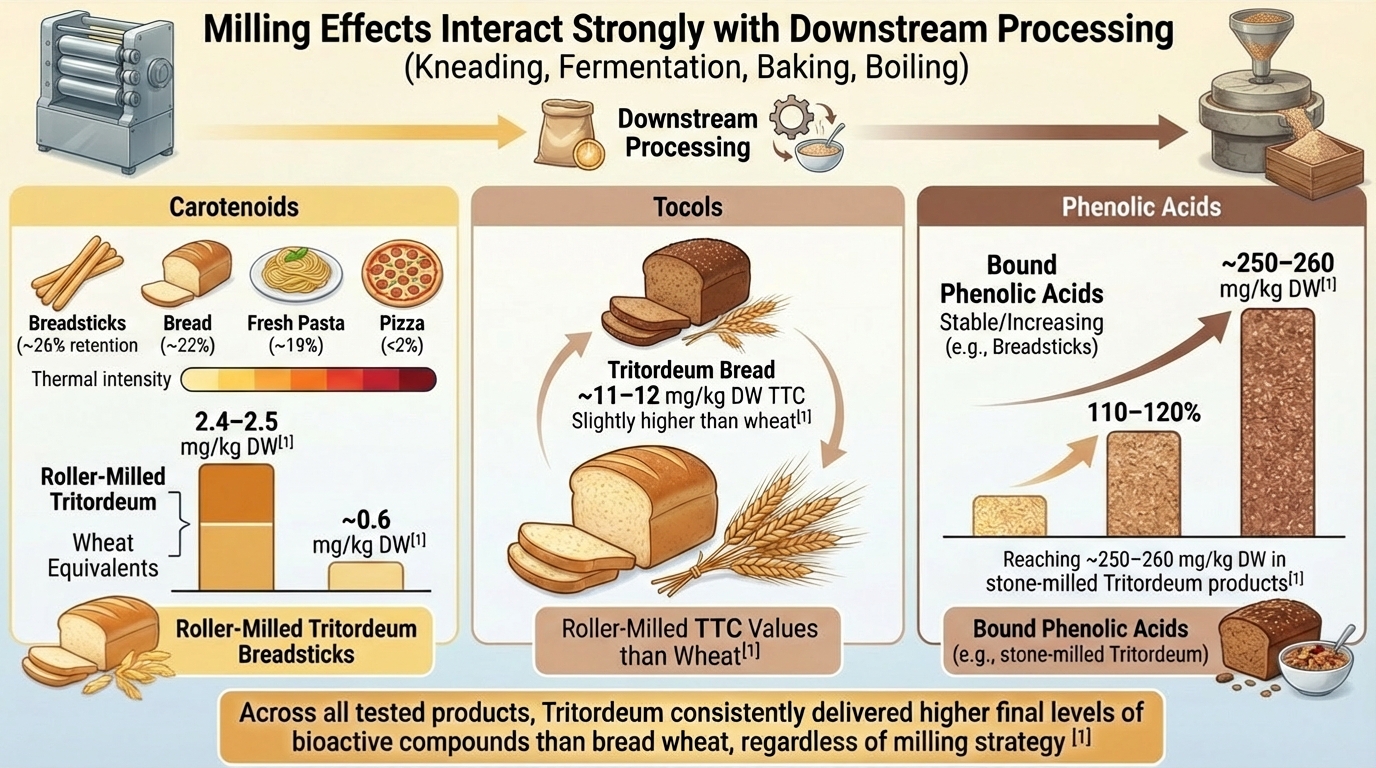

Milling effects interact strongly with downstream processing (kneading, fermentation, baking, boiling):

Carotenoids

Retention from flour to final product ranged from approximately 26% in breadsticks, 22% in bread, 19% in fresh pasta, and <2% in pizza, depending on thermal intensity [1].

Roller-milled Tritordeum breadsticks retained up to 2.4–2.5 mg/kg DW carotenoids, compared with ~0.6 mg/kg DW in wheat equivalents.Tocols

Final TTC values in Tritordeum bread were approximately 11–12 mg/kg DW, slightly higher than wheat, despite similar initial flour values, suggesting improved stability or antioxidant interactions [1].Phenolic acids

Bound phenolic acids were relatively stable during baking and, in some cases (e.g. breadsticks), increased to 110–120% of initial flour values, reaching ~250–260 mg/kg DW in stone-milled Tritordeum products [1].

Across all tested products, Tritordeum consistently delivered higher final levels of bioactive compounds than bread wheat, regardless of milling strategy [1].

| “Processing losses are inevitable, but Tritordeum consistently retains more bioactives than wheat.”

5. Technological and nutritional implications

The quantitative evidence demonstrates that milling strategy enables nutritional targeting in Tritordeum:

Roller milling optimises carotenoid density and colour, yielding refined flours with ≈8 mg/kg DW lutein-rich carotenoids.

Stone milling maximises antioxidant diversity and fibre-associated compounds, delivering ≈50 mg/kg DW tocols and >300 mg/kg DW total phenolic acids.

This dual functionality is uncommon among cereals and allows Tritordeum to be positioned across both refined and wholegrain product categories with scientifically substantiated benefits.

| “Milling strategy enables nutritional targeting: carotenoids with roller milling, antioxidant diversity with stone milling.”

6. Conclusion

Milling is a decisive control point in expressing the nutritional potential of Tritordeum. Roller milling favours carotenoid enrichment and stability, while stone milling maximises phenolic acids, tocotrienols and β-glucans. Importantly, Tritordeum maintains a systematic nutritional advantage over bread wheat under both strategies, reinforcing its value as a flexible cereal platform for evidence-based food innovation.

| “Tritordeum combines nutritional superiority with processing flexibility, a rare advantage among modern cereals.”

Bibliography

Bibliography

Sardella, C. et al. (2026). The effects of milling and processing on bioactive compounds in bread wheat and tritordeum. Journal of Food Composition and Analysis, 149, 108591.

Giordano, D. et al. (2019). Distribution of bioactive compounds in pearled fractions of tritordeum. Food Chemistry, 301, 125228.

Suchowilska, E. et al. (2021). The profile of bioactive compounds in the grain of various × Tritordeum genotypes. Journal of Cereal Science, 102, 103352.

Shewry, P.R. et al. (2023). Comparative compositions of grain of tritordeum, durum wheat and bread wheat. Food Chemistry, 423, 136312.

Zhu, Y., Sang, S. (2017). Phytochemicals in whole grain wheat and their health-promoting effects. Molecular Nutrition & Food Research, 61, 1600852.